Main drive! This car company announced the installation of domestically produced SiC MOSFETs

.jpg)

Recently, FAW Hongqi announced that they will launch two SiC models this year (click here). Yesterday, they also announced new breakthroughs in the silicon carbide field:

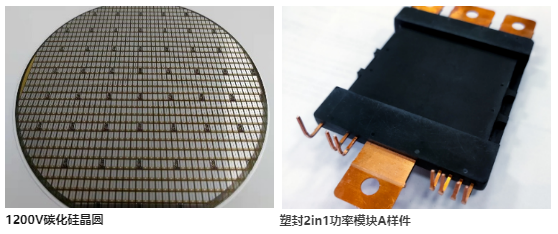

Complete the trial production of the main drive silicon carbide module, using 2in1 plastic packaging, with a parasitic inductance of ≤ 6.5nH, and an output current of 550A;

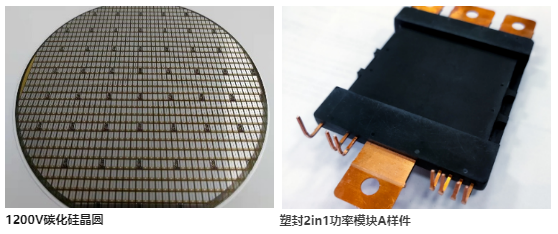

Adopting national production of 1200V SiC MOSFET, with a specific conduction resistance of 3.15m Ω · cm ², The conduction current reaches 120A.

So, which domestic SiC MOSFET is FAW Hongqi using? What are the future boarding plans?

On April 3rd, the official WeChat account of "Hongqi R&D New Horizon" announced that they have completed the first 1200V plastic encapsulated 2in1 silicon carbide power module A sample for nationwide electric drive.

According to Hongqi Company, this main drive silicon carbide module adopts domestically produced SiC MOSFET. Through the application of high-density and reliable cell structure, chip current enhancement technology, highly reliable silicon carbide gate oxygen preparation process, fine structure processing technology, etc., the specific conduction resistance of the chip reaches 3.15m Ω · cm ², The conduction current reaches 120A, and the technical indicators reach the international advanced level.

In terms of silicon carbide modules, Hongqi stated that they have adopted industry-leading three-terminal busbar stacking structure, highly reliable copper wire interconnection technology, and high heat dissipation elliptical PinFin heat dissipation channels. In addition, they are combined with large-sized epoxy resin mold transfer molding and high temperature resistant silver sintered chip mounting technology to achieve a parasitic inductance of ≤ 6.5nH, a continuous working junction temperature of 175 ℃, and an effective output current of 550A.

In terms of electric drive, Hongqi Automobile has independently developed the internationally leading Hongqi HSM high-efficiency electric drive system. The system‘s unique ultra-light and high magnetic density carbon fiber rotor, ultra-high frequency and high-power SiC module, active and passive noise suppression technology, etc., achieve a global leading system efficiency of 95.5% and "zero" perceived noise.

According to "experts say three and a half generations", FAW Hongqi will launch two SiC models in 2023, namely the sedan E001 and the SUV E202.

FAW Hongqi stated that silicon carbide power semiconductors for electric drive in China are still in the hands of a few foreign enterprises. In order to achieve the "black to white" transformation of silicon carbide technology, they have carried out independent technological breakthroughs in new structures, new processes, and new materials through a cooperation model between central enterprises. They have truly achieved the full process localization of key links such as substrate, epitaxial, chip, packaging, and module trial production, achieving independent control.

According to FAW Hongqi, their silicon carbide module was jointly developed by the Power Electronics Development Department of the New Energy Development Institute of Hongqi Research and Development Institute and CETC.

In fact, China Electronics Technology Group mentioned on its official website on March 21st that its researchers are conducting key technical research on high current density silicon carbide device design, high stability wafer production control, and other key technologies in comparison to the demand for high current silicon carbide MOSFET chips for electric drive proposed by leading new energy vehicle enterprises.

In addition to the main drive, the silicon carbide MOSFET produced by CETC has been adopted by other domestic car companies before this, and it is reported that the current product loading volume has reached one million units.

In March of this year, Chief Expert Bai Song of China Electronics Technology stated in an interview with Xinhua Daily that they have established and improved chip processes with independent intellectual property rights in the field of silicon carbide, such as JBS diodes and MOSFETs, forming the 650V-6500V series of products. Moreover, their team successfully launched the second generation silicon carbide MOSFET product in 2022. Compared with the first generation product, the chip area was reduced by 30%, the conduction loss was reduced by 15%, and the power conversion efficiency was significantly improved.

It is worth noting that on May 25th, CETC will participate in the "Automotive and Optical Storage SiC Application and Supply Chain Upgrade Conference" held in Shanghai, and will bring their wonderful speeches at the conference to learn more about CETC‘s silicon carbide technology and progress. Please scan the QR code and register to attend as soon as possible.

.jpg)

.jpg) Recently, FAW Hongqi announced that they will launch two SiC models this year (click here). Yesterday, they also announced new breakthroughs in the silicon carbide field:

Recently, FAW Hongqi announced that they will launch two SiC models this year (click here). Yesterday, they also announced new breakthroughs in the silicon carbide field:

.jpg)